The quest for greater energy efficiency has been promoted by the government using utility company programs for more than a quarter of a century. This movement has made consumers aware that higher efficiency equipment is the right thing to use. Manufacturers have responded with higher efficiency equipment and contractors have consistently been able to increase the sales price of their systems because of this.

An increasing number of HVAC contractors are voluntarily measuring the performance of the HVAC systems they install. They do it because their customers are willing to pay extra for the assurance of increased efficiency and verified comfort. Let’s take a closer look at system performance measurements and how you can use them to solve your customer’s comfort and efficiency problems and increase sales.

Contractors Capitalize on Efficiency

During this same period of time, leading HVAC contractors took the concepts from utility company programs and began to infuse their sales opportunities with the idea of testing. Since they had a relationship with the customer and were able to work directly with them to make the buying decision, testing evolved into a key component of the sales process.

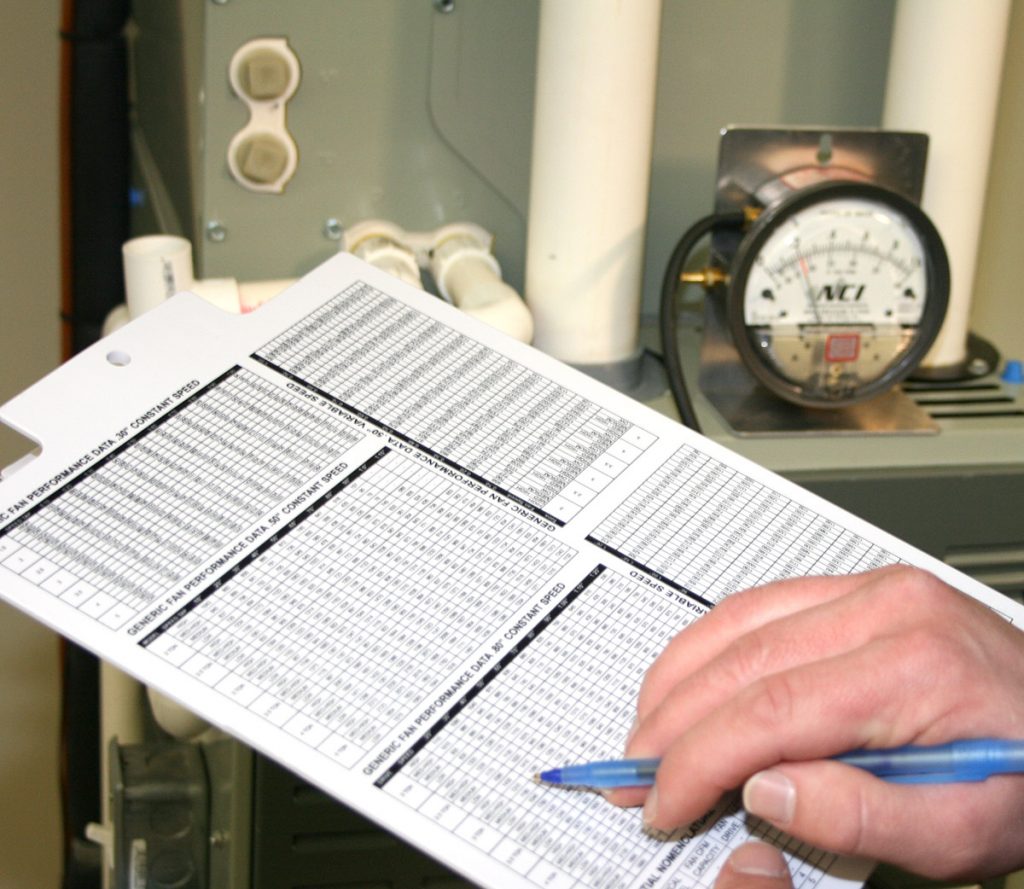

Testing and diagnostic methods were used and were tied to live system-testing HVAC contractors were accustomed to. Air balancing and combustion efficiency testing measured the performance characteristics of the HVAC system and compared the collected information to manufacturer’s specifications.

When this testing is used today, customers are invited to become involved in the testing and diagnostics of the system, and a contractor/customer bond is created. Using an air-balancing hood enables the customer to “see” and relate to airflow. By including the customer in the testing process, it will be easier for the contractor to convince the customer that a kitchen that has been uncomfortable for years requires airflow of 100. The contractor should use the balancing hood to show the customer that the measure of airflow is only 35.

Customers quickly understand the cause for inefficiency and desire to have the problem solved. In addition to getting a new box that heats or cools, they will now gain comfort in a room that previously had none.

The Equipment and the Ducts Make a System

Efficiency is purchased when duct and equipment defects are discovered using easy to understand live system diagnostics. An air-balancing hood is a good method for basic pressure and temperature testing, and can be very effective at identifying defects that prevent efficiency, comfort, and safety.

Keep pre-sales testing simple and to a minimum. When a customer sees enough to buy, stop testing and make the sale. Additional testing and diagnostics will be needed to form a detailed scope of work for the installers. The work can be priced and sold to meet your customer’s budget and efficiency needs.

A Live One-Hour Infomercial

System performance measurement works because what you’ve created is a live one-hour infomercial. You’ve educated and motivated your customer to get more than a new box that did the same thing the old one did. Typically the sale increases by a third, but more importantly, you can now actually deliver the efficiency and comfort that others can’t.

Through testing and diagnostics with the customer you also exposed the feeble attempts of your competition to sell a high efficiency box that cannot deliver what they promised it could. Your customers win and you win.

Capitalize on the Value of Verification

Your customers trust you. They commit to being your customers and you commit to being their trusted contractor. By adding system performance measurement before and after the sale, you can raise the level of trust and seal that promise by inviting your customers to witness for themselves the results of your work.

What’s most important is you can now deliver to your customers what you’ve been promising them for years. They’re willing to pay you to deliver the quality and efficiencies others talk about, but are unable to deliver.

All the government and utility programs want is for you to capitalize on what they’ve tried to offer for decades. They’ve created the demand, that’s their job. Yours is to deliver to your customers what they have wanted and are willing to pay for all along.