Economizers are in the spotlight as a prime opportunity for energy savings in the commercial HVAC marketplace. It’s said, with little argument from those in the field, that nearly 80% of air-side economizers are non-functional. So if that’s true, opportunity is calling any mechanical contractor willing to step up and take this bull by the horns.

Two Big Questions

The first question is why are such a large percentage of economizers non-functional? Many believe that most economizer manufacturers cheaply build products that have an extremely short life expectancy — just to meet codes.

This may therefore explain the 80% non-functioning number. Or is the real answer in the next question?

Why aren’t economizers being repaired? Another interesting number circulating in the field is that 80% of economizers are never commissioned when installed. This statistic points the finger directly at the HVAC industry. In reality, few installers or contractors really know how to commission an economizer or how to set the controller for local weather conditions. Even fewer really know how to measure and set airflow through an economizer.

The bottom line: perhaps as an industry we lack the knowledge to keep our customers in free cooling. If that is the case, companies willing to specialize in economizer repairs and upgrades have tremendous opportunities.

Three Economizer Opportunities

Meanwhile, interviews with several top commercial contractors in areas of the country where economizers pay off handsomely led to the creation of this Top Ten list of economizer defects (and opportunities). These are defects most frequently discovered in the field. It is interesting to see how little it takes to get an economizer back up and running to deliver free cooling when outside conditions are right.

Unplugged economizers. The number of economizers with this classic problem is so great that the problem begs a closer look. It seems the only reason economizers are unplugged is because many installers are so unfamiliar with what it takes to set them up that they don’t even try. That brings us back to the opportunity; it may be much greater than any of us anticipated.

Frozen actuators. If economizers are as cheap as indicated, this would support the decision to replace a locked-up actuator with a new one that may last the life of the equipment. Now that brings us to selling repairs. For a commercial building owner to agree to pay for an economizer reconditioning, they usually want some kind of payback on the investment in his building. You can help the client by calculating economizer savings in his marketplace. Check out this free download tool at the Honeywell website. It’s easy-to-use and the price is right.

Economizer not commissioned at start-up. This opportunity comes from contractors who fail to train their installation crews. You know … specifically from those low bidders who take the job for bottom dollar and the customer pays the difference over and over again in the years that follow. Oh, you haven’t trained your installers in economizer commissioning? We need to talk.

More Opportunities

Carbon Dioxide sensors out of calibration. Economizer sensor lifespan and accuracy, meanwhile, are both increasing rapidly as technology advances. Demand control ventilation is in fashion and it just makes sense. Today, sensors have much to offer and are often easy change-out options for aging or inaccurate sensors. A short conversation with your controls vendor will shed some light on this opportunity.

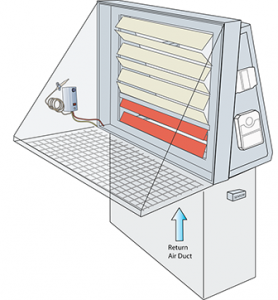

Economizer components work together to control and deliver: Minimum ventilation air, Regulation of building pressure, Temperature and humidity control, Indoor Air Quality, and Free air conditioning

Damaged actuator motor fiber gear assemblies. Only the best technicians take the time and make the effort to watch an economizer cycle — inspecting for evidence of stripped cogs. When this happens, the louver position changes a little with each cycle and can really mess up louver airflow settings. Replacement gears are available. Keep them on hand. They should be replaced often.

Five More Opportunities

Pre-filter damaged or missing. Air filters located in the intake of an economizer are easy to overlook. Just keeping those filters clean can make a big difference in long-term economizer operation and in extending the life of components that should, ideally, remain clean.

RH sensors out of calibration. Only the best technicians carry the 33% and 75% pots of saline solution on their trucks to calibrate these sensors. Believe it or not, some older sensors specifically need recalibration every 3-6 months. Best practice is to replace old sensors with new ones that are more accurate and dependable.

Damaged or loose linkage. Adjusting linkage is an art. Doing so requires patience and skill. Taking the time to drive economizers so they open and close is the only realistic way to check linkage operation and functionality. Tighten regularly and don’t forget to measure economizer airflow.

Corroded wiring. So how long does economizer wiring last in your part of the country? Good contractors make a practice of salvaging old economizers when replacing equipment and use them as trainers to provide hands-on rewiring exercises. That’s a good idea, give it a try.

Conclusion

So, as you can see, economizer opportunity abounds. If you are in an area of the country where economizers make great sense, consider investing a little time and a few marketing dollars preparing your service department for a great harvest. Fall is coming. Free air conditioning will be everywhere.

Leave a Reply

You must be logged in to post a comment.