If you’ve been in the HVAC industry for any length of time, you’re familiar with complaints involving dust and dirty equipment. As a result, most technicians target the air filter first when they receive such calls. As you investigate these problems, keep in mind how the following ways reduce filtration effectiveness so you can more accurately diagnose these issues.

#1: Poor Rack Design and Installation Kills

Filtration Effectiveness

One of the most common issues reducing filtration effectiveness is the design and installation of the filter rack. Poor fitting racks with inadequate seals allow unfiltered air to move around the filter instead of through it.

When installed at the air-handling equipment, this bypass and leakage often results in dirt accumulating on the blower wheel, indoor coil, and secondary heat exchanger. A visual inspection and attention to detail typically reveals this issue. As you examine the systems you maintain and service, you can often discover gaps a cat could be pulled through.

As you examine the systems you maintain and service, you can often discover gaps that are big enough for a cat could be pulled through.

Note: if the filter is sized correctly, the repair is minor – you’ll need sheet metal, gaskets, and silicone. But if the filter is undersized, the repairs are more involved. Many contractors will offer upgrades that include a sealed rack with a properly sized filter.

#2: Filter Grilles and Duct Leakage

Air filtration is negatively impacted in so many ways. It is important to change filters regularly, but air is sneaky and can find many ways to escape, reducing filtration effectiveness.

Filters installed in remote return grilles tend to have two possible sources of reduced filtration – the grille and return duct leakage. If you’ve ever heard a filter move back and forth in the grille as the blower turns on and off, you’ve encountered a poorly fitting filter grille.

As you probably know, air takes the path of least resistance. Remember that dirt travels along with it. Poorly fitting filter grilles result in unfiltered air moving into the system. You’ll often notice this as dust streaking on the exiting air-side of the filter.

Duct leakage isn’t as obvious a problem unless you dig deeper. Pressure in a system increases as you get closer to the blower. This means duct leakage increases near the air handling equipment. Any unsealed penetrations in the return duct between the filter and equipment allows unfiltered air to enter the duct system. This is air you don’t want to breathe from sources such as an attic, crawlspace, or garage.

As you probably know, air takes the path of least resistance. Remember that dirt travels along with it.

You can correct this with gasket material at the filter grille and some targeted sealing of the return ducts. Before performing this work, be sure you properly size filter grille and return ducts.

#3: Excessive Filter Face Velocity and its Impact on Filtration Effectiveness

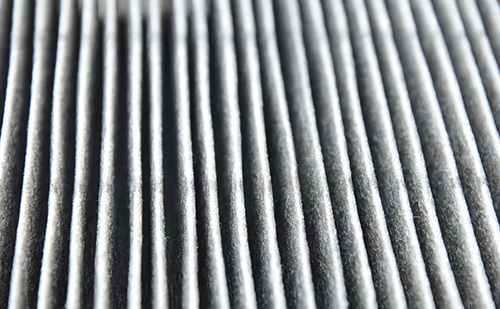

The next problem can show up with a perfectly sealed filter rack and duct system. Excessive face velocity pulls dirt through the filter media instead of capturing it. You’ll typically encounter this when the media is undersized for the quantity of air it is designed to clean.

This is one of the reasons pleated and electrostatic filters have such a bad reputation. It isn’t the filter media itself — it’s the size that’s the problem. Each filter media type has a range of air speeds designed to effectively operate within. When you exceed this range, the filter cannot capture particulate so it passes through. It then accumulates in the equipment or moves through the duct system.

You’ll need to do a bit of design work to correct this issue. Make sure to properly size the media for the application. If interested in learning more about this, email me for a free procedure on how to size an air filter and improve their performance.

#4 Air Handler Cabinet Leakage

In recent years, equipment manufacturers have done a better job reducing cabinet leakage. However, there is still a lot of equipment out there that needs your help. Filter access panels, electrical penetrations, and cabinet leakage allow unfiltered air to move around the filter and introduce pollutants into the system.

Think twice about using mastic to reduce cabinet leakage. The service department might hunt you down if you choose to use it.

This problem is similar to poor filter rack design. Correct it using similar principles. You’ll use more silicone and gasket material to reduce cabinet leakage and assure air passes through the filter. Attention to small details can reap big rewards when solving this issue.

Remember, if you decide to reduce cabinet leakage, seal the panels in a manner that allows for access into the equipment later. Think twice about using mastic to accomplish this, the service department might hunt you down if you do.

Look Beyond the Equipment

So don’t forget to consider other sources of dirt and dust from exterior sources that may never make it to the air filter. These include insulation fibers, pet dander, and the vacuum cleaner that blows as much back into the room as it picks up.

In conclusion, it’s important to remember the building connects to the HVAC system and has as much, if not more, influence on the dust problems you deal with.

David Richardson serves the HVAC industry as a curriculum developer and trainer at National Comfort Institute, Inc. (NCI). NCI specializes in training focused on improving, measuring, and verifying HVAC and Building Performance.

Do you want a free filter sizing procedure? Just contact David at davidr@ncihvac.com or call him at 800-633-7058. NCI’s website www.nationalcomfortinstitute.com is full of free technical articles and downloads to help you improve your professionalism and strengthen your company.